ukážka výrobného procesu stavby lietadiel

Výroba a testovanie

Production and testing

Demonstration of production process

1. Custom modeling and construction

The Viper SD4 and Skyper GT9 aircraft are TomarkAero’s own products. Evidence of the joint creative work of Slovak specialists is also the “Engineering Product of the Year” award, which was awarded to both TomarkAero – Viper SD4 and Skyper GT9 aircraft. Aircraft are therefore not only manufactured, but also constructed and modelled by their own experts in the field of aeronautical construction and development. All this is carried out by top experts from the development, construction and modelling departments.

2. Divide of material

State-of-the-art laser technology is used for the basic cutting of durable aluminum sheets (aluminum alloys with additives), which can cut parts of the highest quality. This activity is followed by bending and changing the shape of the sheets to the final form for the purpose of aircraft construction.

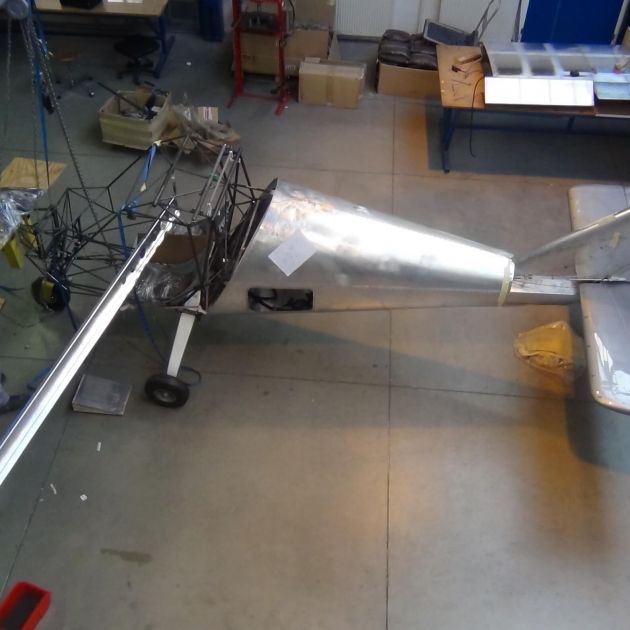

3. Construction of the fuselage

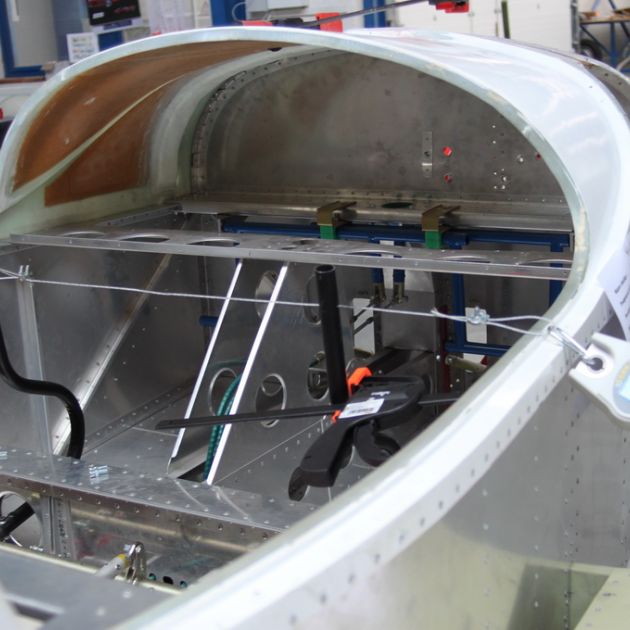

Other activities are related to the construction of the fuselage, aircraft hub, wings, tail surfaces and other parts of the Viper SD4 and Skyper GT9 aircraft. The riveting process is used to attach individual parts of the aircraft. The aircraft is connected by thousands of rivets, which hold the metal structure firmly and are extremely important also from the safety point of view.

4. Finalization of aircraft construction

After the completion of the supporting parts of the aircraft, the engine installation, electrical installation of instrumentation and other work on the finalization of the aircraft construction (cabin, interior, painting works) are underway. We pay particular attention to the thorough inspection of the entire production process. Each process is subject to regular measurement and evaluation of measured values to verify correct completion and full functionality.

5. Inspection and testing

Inspections shall be followed by flight tests and final inspection. Only after a detailed inspection aimed at verifying the functionality of each part of the aircraft, elements and sub-assemblies, is the aircraft dispatched to the customer. The whole process, from initial production to final inspection, is carried out with an emphasis on accuracy, precision, while maintaining the highest quality of all activities.

Corkscrew tests (SPIN tests)

The Viper SD4 has passed the corkscrew tests for EASA CS-LSA certification. The result of the SPIN tests means a high level of aircraft safety. Note the calm and prudent behavior of the test pilot. The Viper SD4 meets safety requirements in the event of unwanted entry into the corkscrew.

WARNING:

Corkscrews are forbidden on the Viper SD4 aircraft!. The manufacturer forbids corkscrews! The video shows the ability to handle corkscrews. The test was carried out by a professional pilot, with special training and equipment.

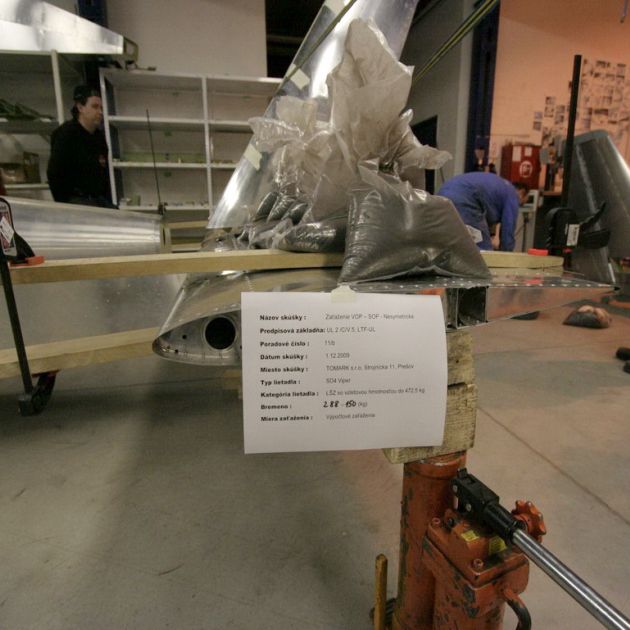

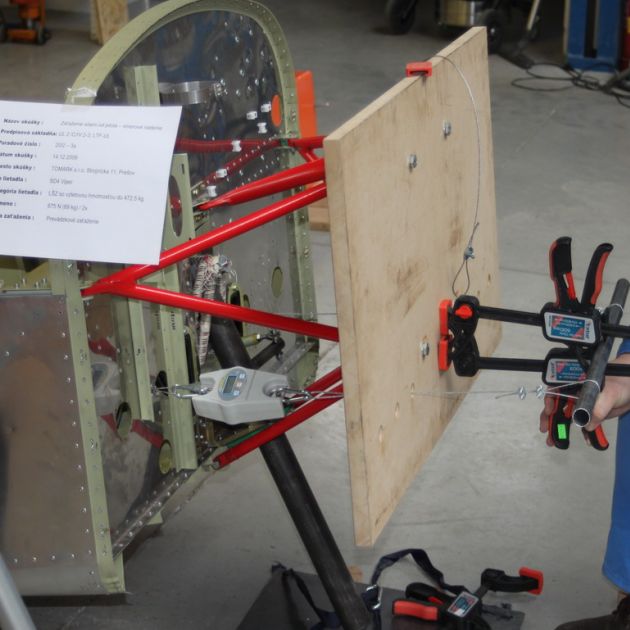

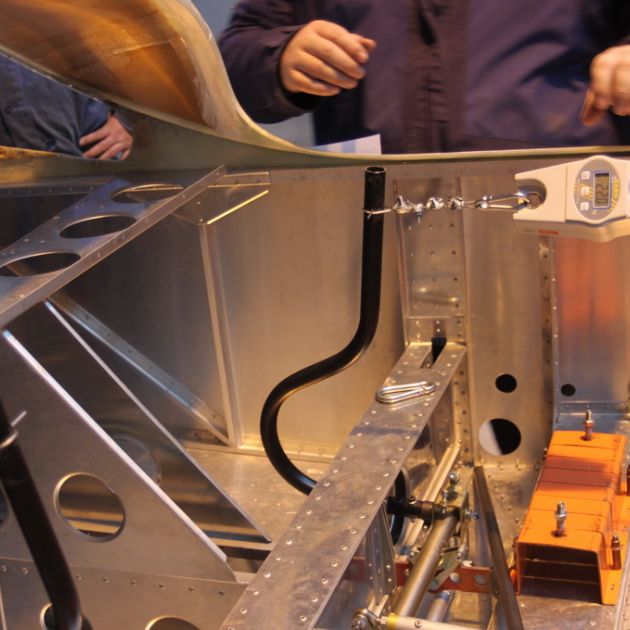

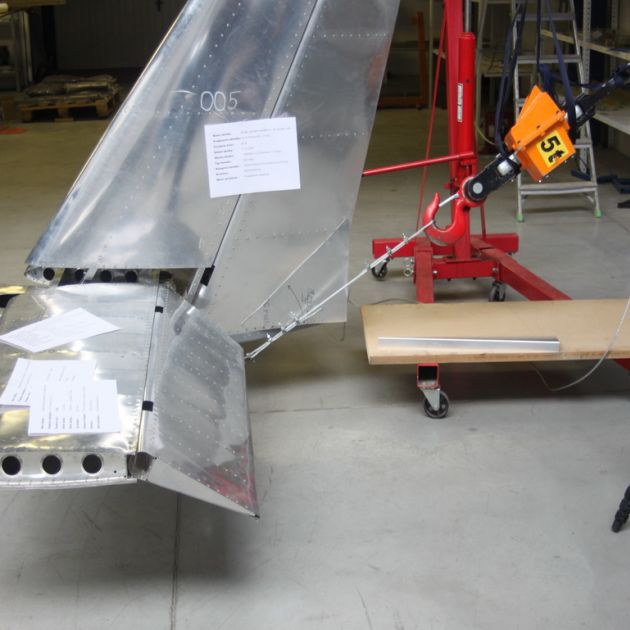

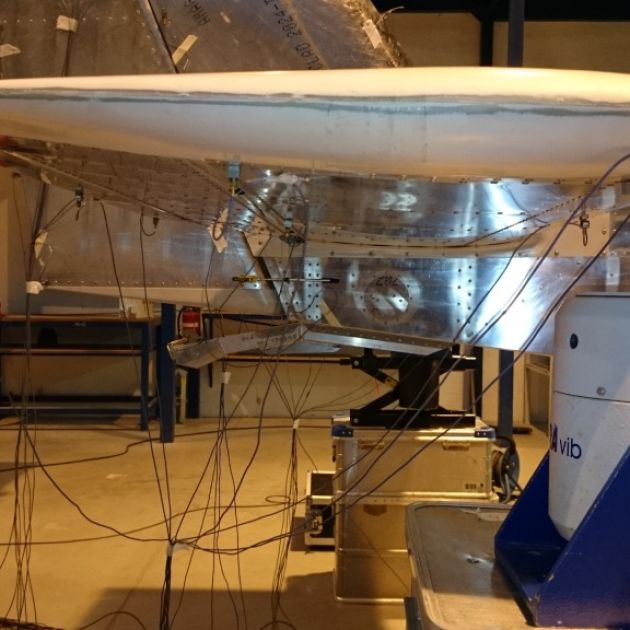

Strength and Flutter tests

At the end of 2009, we were supervised by Ing. Václav Chvála, Chief Inspector of the ULL technique of the Czech Amateur Aviation Association, successfully carrying out tests of the strength of the aircraft structure at various loads. The test consisted of strength tests of the hull, wings, wings, buoyancy flaps, tail surfaces, chassis, engine mounting and steering system according to the Czech UL-2 regulation and the German LTF UL regulation. The strength of the wing was tested up to its fracture, which occurred at a design load of 5.3 g x 1.5 at a maximum take-off mass of 472.5 kg. The strength tests of the horizontal and vertical tail surfaces were carried out at various prescribed load combinations. The chassis test also included the so-called drop test.

Part of the certification process – EASA Viper SD4 type certification, is also the execution of ground vibration tests. The result of vibration tests is that there is no dangerous phenomenon during operation at design speeds on the Viper SD4 aircraft – the vibration of the aircraft control surfaces (Flutter). As part of conducting vibration tests, we also implemented a process of comparing injected and expelled wavelengths on aircraft control surfaces. Thanks to the oscillating frequency devices, the vibrations oscillate the aircraft, then the wavelength is read. The resulting vibrations generate the sound of the aircraft on the control surfaces.